AJM Engineering

More than 55 years of manufacturing quality precision engineered parts, moulds and tools to a variety of market sectors. Our team of highly skilled precision engineers manufacture complex parts to extremely high tolerances specialising in hard to machine exotic materials. Founded in 1964, our family run business which celebrated its 50th year in 2014, continues to represent high quality across a variety of market sectors!

Founded in 1964

Family Run Business

Consistent Project Quality

Our Services And Capabilities

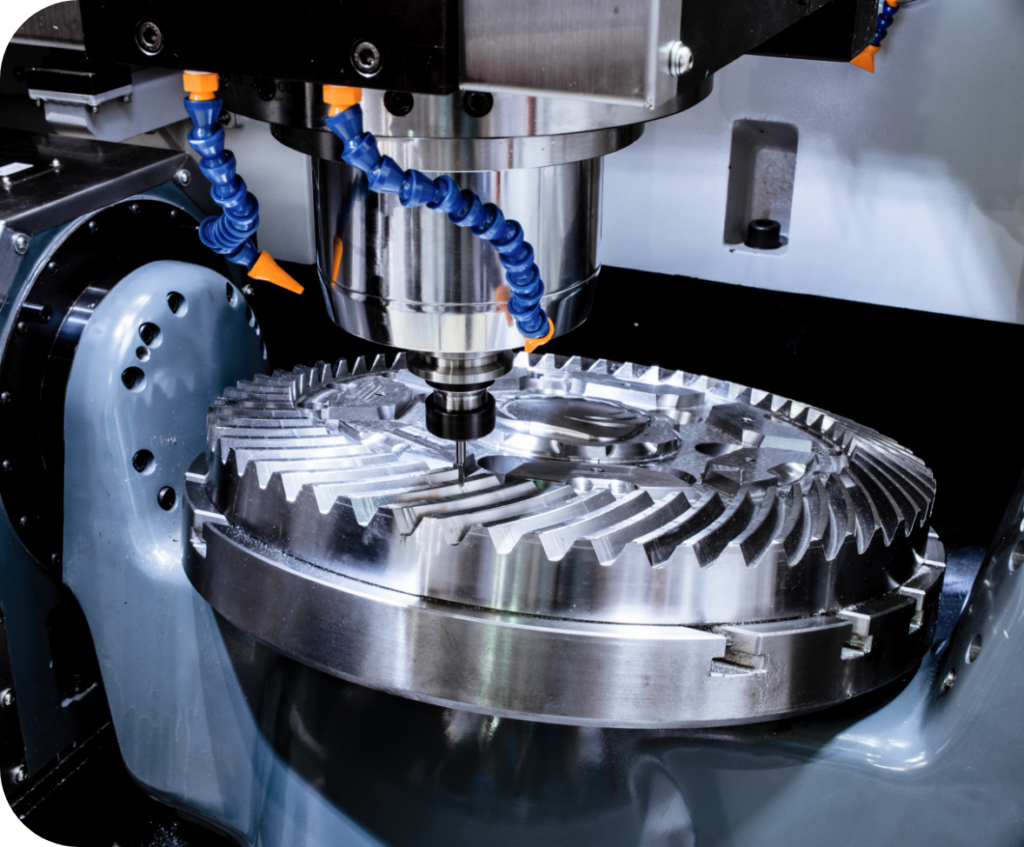

Precision Engineering

All of our management and production staff are experienced engineers and we strive to push the boundaries of what is technically possible. Our reputation is built on undertaking difficult projects in a variety of challenging materials and seeing them through to a successful conclusion.

Mould and Tool Makers

Our in-depth knowledge of Mould and Tool making supported by the latest technologies ensure your design requirements are reflected in the quality of your final product.

Manufacturing

We perform a variety of operations within many sectors; full or part manufacture, low, medium or high volume, prototype parts, precision engineering, moulds and tool making components.

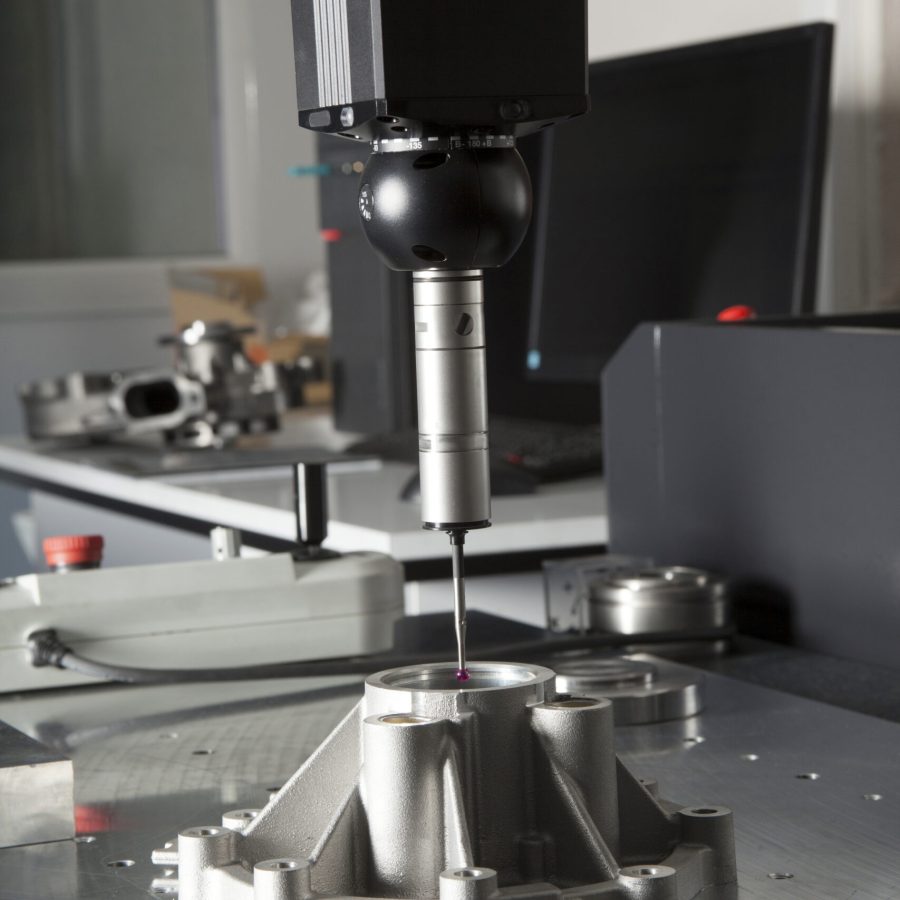

Quality Assurance

Our technology permits high precision 3D measurement, imaging and comparison of parts and compound structures within production and quality assurance processes.

What our clients say

“Over the last approximate period of 12 years I have worked with AJM as a supplier for different companies. The work that has been completed during that time has covered many different products and has often included prototype design work where they have actively contributed in design modifications to make products more manufacture friendly and more economic on price. I would consider AJM amongst any Tier 1 supplier I have ever used and would highly recommend to any company looking for a manufacturing partner.”

“We have used AJM on multiple occasions over the last six years on various engineering projects.

We have always found their work to the highest standard and to always be helpful and flexible in making certain the job is just how we want it. I am certain our working relationship will continue for years to come.”

Our Sectors

Renewables

This is an area AJM is currently developing and sees this as a key sector where AJM manufacturing skills and techniques can be put to use – complete the contact us section on the web site if you have a project or require parts to be manufactured.

Our Sectors

Oil & Gas

For over 15 years AJM has worked with global organisations to manufacture a comprehensive range of parts for the oil and gas industry. AJM understands the industry requirement for product precision and have experience in machining a range of unique materials needed for onshore and offshore applications. One off to large batches of parts can be shipped within the UK or exported to countries around the world. Complete the contact us section on the web site for more information.

Our Sectors

Aviation

Since gaining AS9100D certification in 2018 AJM has manufactured parts in a range of materials and machined forgings to Customer drawings for the international commercial and military aerospace industry. AJM has also produced moulds and tools for the UK National Composites Centre based in Bristol. Please contact us for more information.

Our Sectors

Military

AJM has manufactured parts and moulds for use in the military sector. From contract parts for DSTL in the UK to production and refurbishment of moulds for Customers who directly produce parts for the Military in the UK and around the world AJM can help – please contact us for more information.

Our Sectors

Dairy

AJM manufactures and refurbishes moulds and tools for the Dairy industry in the UK and around the world. Recently this has included production of multi cavity rubber injection moulds which will be loaded and unloaded by robots – please contact us for more information.

Our Sectors

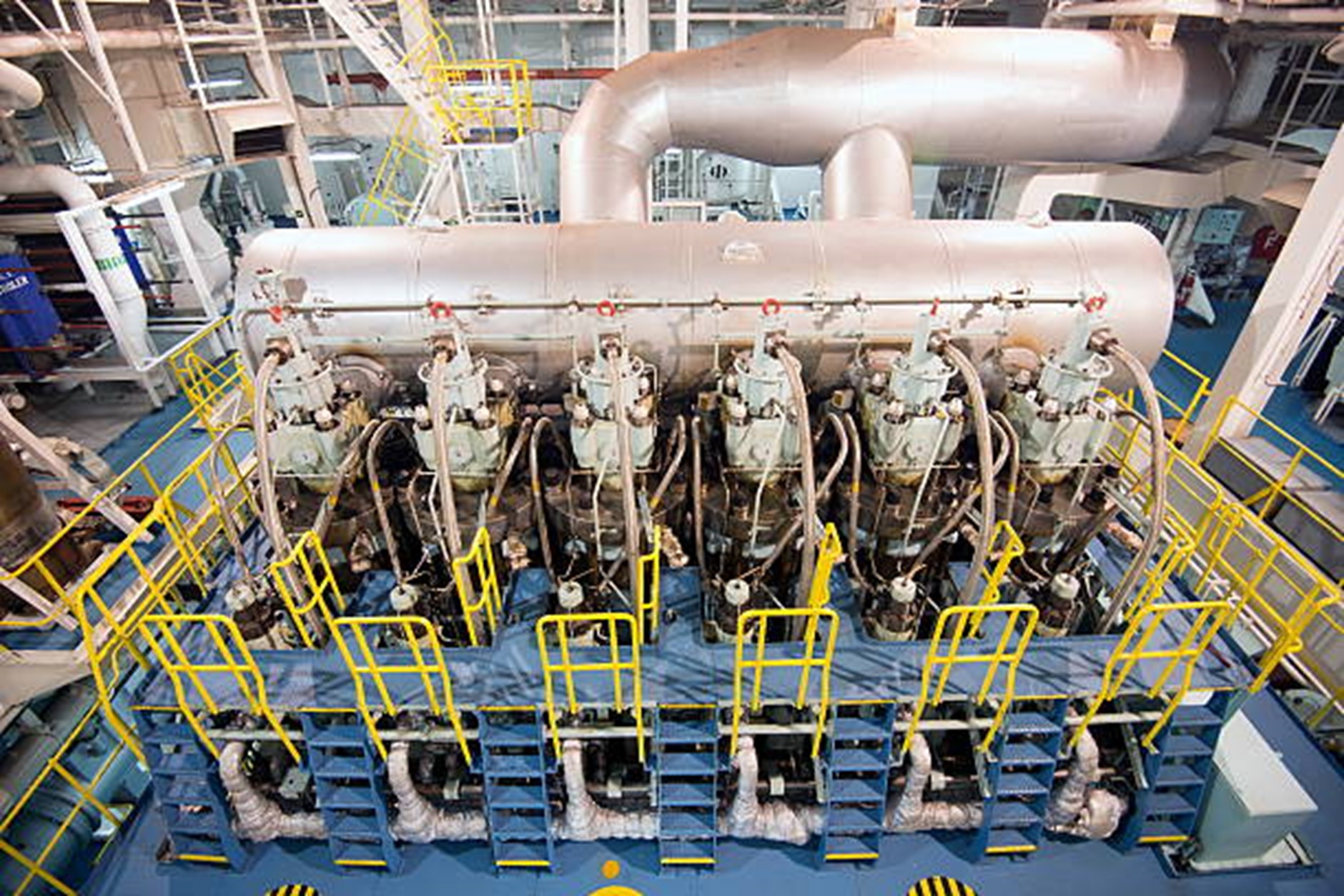

Marine

AJM works with global organisations to manufacture a range of parts for the marine industry direct from a range of marine grade materials or forgings. This can include manufacture of spare parts for equipment which has been in the field for a number of years – please contact us for more information.

Our Sectors

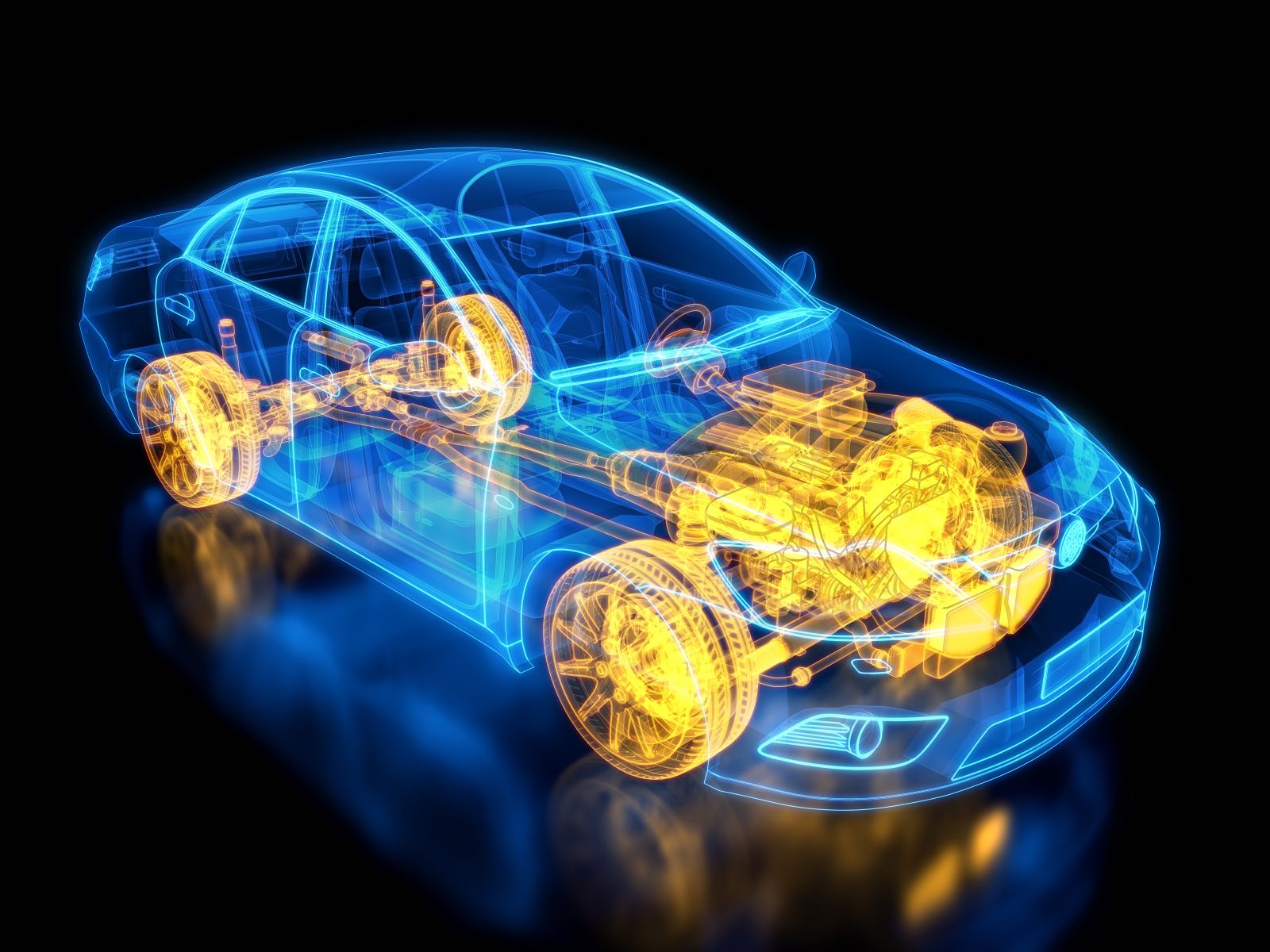

Automotive

AJM works with Customers to supply injection moulds and tools used in the production of automotive parts. From simple to complex multi cavity moulds AJM can help – please contact us for more information.

Our Sectors

Nuclear

AJM manufactures tooling for suppliers to the Nuclear industry – Complete the contact us section on the web site for more information.

Our Sectors

Medical

AJM has produced prototype parts and jigs to test out innovative designs before putting into full scale production. Complete the contact us section on the web site for more information.

Contact Us